Leading Formwork and Scaffolding Business Changing Building And Construction Effectiveness

All the shareholders of the firm have actually been involved in the scaffolding and formwork contractors sector for greater than 18 years. AG Formwork & & Scaffolding additionally has the back up of consultants who have in between them over half a century experience in the scaffolding industry. Designed Devices supplies rental scaffolding options for all your job's requirements.

We proudly supply a mix of comprehensive products and services that include Scaffolding, Swing Stage, Mono Rail, Cover, Shoring, Netting, and Systems Scaffolds. All scaffolding provided and erected, complies with the safety and security standards prescribed, specifically the Occupational Health and wellness Act 85 of 1993 & & SANS 10085. The shareholders of KIT finance their belief in the growth of the building market. Their products have been commonly accepted as the standard in South Africa. Our solutions have been developed to give you with the appropriate level of support throughout each phase of your building and construction task. We understand the difficulties that come with operating in the hard African environment which includes dynamic needs and extremely pressurised due dates.

These shutters are custom created, based upon the concrete design and customer spec. Floor Coverers install various kinds of floor covering and floor covering in both property and business buildings. They work with carpets, hardwood flooring, soft ceramic tiles and linoleum-type items made from plastic and rubber. A drywall installer specializes in the installation and ending up of drywall panels in building and construction jobs.

Formwork And Scaffolding Business =================================

Summary of Formwork and Scaffolding

Formwork and scaffolding business play a vital function in the building industry, offering necessary short-lived structures that support structures throughout their growth. Formwork, normally made from products like wood, steel, or plastic, forms and sustains concrete while it treatments, ensuring that it establishes properly. Scaffolding, on the various other hand, uses a secure system for employees to gain access to different heights securely and supplies assistance for materials and tools. Together, these systems enable effective building processes, improve safety, and are important to the success of any structure job.

Meaning of Formwork

Just as importantly, low quality formwork and scaffolding can place your business in jeopardy of litigation and prosecution under regional and nationwide safety and security laws. We deal with our customers to offer them with the maximum formwork solution that offers versatility and expense performance. Our diverse production capability allows us to offer basic steel remedies too. Our consumer base consists of all the leading formwork and construction firms in your area. We have also provided formwork to a number of nations in Africa and Europe.

With over half a century of experience, Form-Scaff have actually offered product or services to a wide variety of construction and civil engineering industries. We comprehend that every building and construction task has unique obstacles and we are here to assist. Our substantial inventory of high-quality items from trusted brands guarantees you'll have the materials you need within your reaches. If we do not have what you're seeking in stock, our skilled group can locate products and supply them promptly to keep your project on time. At L&W Supply, you'll find a one-stop service for your construction requires.

Formwork and scaffolding play essential duties in the building industry, supplying essential assistance and framework throughout the structure procedure. Both aspects are basic in making certain safety, stability, and efficiency on building and construction websites.

Formwork describes the short-lived or long-term mold and mildews right into which concrete is poured to form architectural components such as walls, pieces, and beam of lights. learn this here now develops the preferred form and holds the put concrete in place till it solidifies. Generally made from materials like wood, metal, or plastic, formwork can vary in intricacy, varying from basic, single-use choices to innovative systems created for repeated usage.

Meaning of Scaffolding

Formwork and scaffolding are necessary components in the building industry, providing crucial support and structures for building tasks. Formwork describes the momentary structures used to mold concrete up until it solidifies, while scaffolding serves as a system for workers, tools, and materials, making sure safety and security and accessibility at raised elevations throughout construction tasks.

Scaffolding is defined as a temporary structure made use of to support workers and materials during the construction or repair service of structures. It includes different parts such as systems, criteria, dental braces, and guardrails, all designed to provide a secure working environment at various heights. Scaffolding allows building and construction groups to get to hard areas, improving performance and efficiency while sticking to safety and security policies.

Value in Construction

Formwork and scaffolding play essential functions in the building and construction market, supplying crucial assistance and framework during the structure procedure. Formwork refers to the temporary or irreversible molds used to hold concrete in place till it remedies and gains sufficient stamina. It incorporates a variety of materials and systems, including traditional wood, steel, and plastic kinds. On the other hand, scaffolding consists of momentary frameworks used to sustain employees and products at elevated heights, making sure safety and security and ease of access for different tasks throughout building.

The importance of formwork and scaffolding in building can not be overstated. They enhance safety by supplying secure systems for workers and preventing crashes during vital phases of building. In addition, reliable formwork systems can bring about a more efficient putting and treating procedure for concrete, decreasing delays and boosting top quality. Scaffolding likewise assists in the job of tradespeople by providing easy access to different degrees of a framework, thus streamlining job timelines.

Moreover, firms focusing on formwork and scaffolding add significantly to the general success of construction jobs. They provide experienced suggestions on the very best systems to use based upon project requirements, budget plan, and website problems. The use of advanced materials and modern technologies by these companies can cause ingenious solutions that maximize workflow and lower labor expenses. By teaming up with experienced formwork and scaffolding companies, building firms can guarantee the structural integrity of their jobs while focusing on security and performance.

Kinds of Formwork

Formwork plays a critical duty in the building and construction industry by offering momentary structures that shape and support concrete till it sets. The types of formwork readily available can differ considerably, each created to satisfy certain job demands and challenges. From conventional wood formwork to contemporary modular systems, recognizing the various sorts of formwork is essential for scaffolding and building firms intending to optimize efficiency, security, and cost-effectiveness in their jobs. This post explores the numerous kinds of formwork utilized in the market, highlighting their distinct attributes and applications.

Conventional Hardwood Formwork

Formwork is a critical part of building, offering short-term structures to mold and mildew concrete during the treating process. Amongst the different types of formwork readily available, conventional timber formwork has been widely made use of for many years. This approach entails using wood planks and light beams to create a scaffold-like structure that holds the wet concrete in place till it hardens.

Typical wood formwork is favored for its flexibility and ease of modification. Carpenters can quickly shape and change the hardwood to fit particular style demands, making it ideal for facility or special structures. In addition, timber is conveniently offered and usually cost-effective, permitting cost-effective building remedies.

One substantial advantage of traditional hardwood formwork is its ability to generate smooth finishes on the concrete surfaces. By using well-prepared wood, the resulting concrete can call for marginal ending up work, saving time and labor costs. However, this method does include some drawbacks, such as the need for competent labor to put together and dismantle the formwork and the possibility for hardwood to warp or deteriorate when revealed to wetness.

Despite the increase of modern-day formwork systems, standard timber formwork remains to be a useful choice, particularly in projects with complex styles or where versatility is required. As building and construction needs progress, formwork and scaffolding business remain to stabilize making use of cutting-edge materials with conventional approaches to attain the most effective lead to their jobs.

Engineered Formwork Systems

Formwork is an important element in building, providing the temporary structure required to shape and sustain concrete till it can establish and gain enough stamina. Different types of formwork are readily available, each suited to different applications, and among these, engineered formwork systems play a critical function in enhancing effectiveness and safety and security on building sites.

One typical type of formwork is standard wood formwork, where wood boards and dental braces are utilized to produce molds for putting concrete. While cost-efficient, this technique can be labor-intensive and much less specific. In contrast, crafted formwork systems use pre-fabricated components made from materials such as steel, light weight aluminum, or high-strength plastic. These systems are designed for faster setting up and disassembly, significantly decreasing labor time and prices.

Amongst engineered formwork systems, panel formwork attracts attention due to its modular layout. Panels can be conveniently linked and adjusted to create various sizes and shapes, making it functional for various construction tasks. One more preferred selection is passage formwork, utilized primarily in recurring structures like apartment. This system permits the synchronised pouring of wall surfaces and slabs, improving the building procedure.

Climbing up formwork is one more innovative designed system, usually used for skyscraper structures. It involves formwork that can move up as the building proceeds, supplying ease and stability during concrete putting at elevated heights. In addition, table formwork, designed for big locations such as floors and ceilings, uses quick arrangement and removal while keeping architectural stability.

With innovations in technology, numerous formwork and scaffolding firms now use tailored engineered solutions that accommodate the particular demands of each construction job. This not only enhances safety and security and performance however likewise supports lasting techniques by lowering waste and resource use.

Finally, recognizing the different kinds of formwork, particularly crafted formwork systems, is important for building business intending to optimize their operations while ensuring top quality results. These systems offer substantial time financial savings and adaptability, inevitably contributing to the success of construction jobs.

Plastic and Steel Formwork

Formwork is essential in the construction sector, giving the essential shapes and support for concrete until it remedies. Among the various products utilized for formwork, plastic and steel are 2 popular types, each with its unique advantages and applications.

Plastic formwork is made from lightweight products that are simple to deal with and construct. It is excellent for small to medium-sized jobs as a result of its cost-effectiveness and versatility.

On the other hand, steel formwork is known for its resilience and toughness, making it suitable for larger and extra complex building and constructions. Its recyclable nature can bring about substantial financial savings in the long run.

- Plastic Formwork:

- Lightweight and very easy to move

- Economical for tiny projects

- Resistant to water and chemical damage

- Quick setting up and disassembly

- Steel Formwork:

- Extremely resilient and multiple-use

- Perfect for large buildings

- Provides excellent surface area finish

- Much more expensive however supplies long-term expense benefits

Selecting the ideal kind of formwork is critical for reliable project implementation, and both plastic and steel choices existing special benefits tailored to certain building needs.

Modular Formwork Solutions

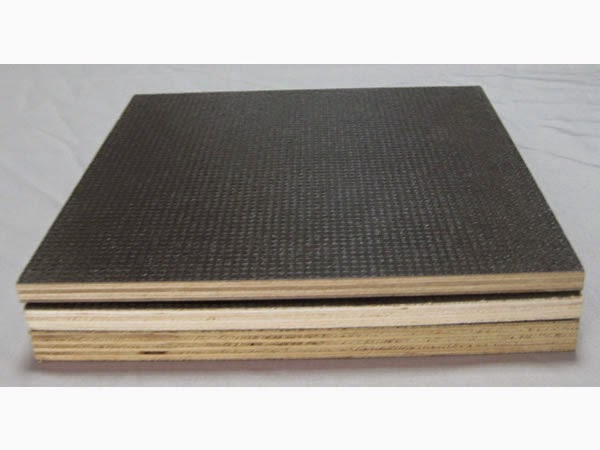

Formwork is an essential element in building, giving the temporary structure required to form and sustain concrete till it cures and gets to the necessary strength. Various types of formwork deal with various building and construction needs. Traditional formwork, made from hardwood and plywood, is widely utilized for its accessibility and cost-effectiveness, although it can be labor-intensive. Steel formwork uses toughness and reusability, making sure consistency in surface area coating and decreasing construction time, while aluminum formwork is lightweight and easy to manage, making it suitable for skyscraper building.

Modular formwork solutions represent a considerable advancement in formwork modern technology. These systems make up pre-engineered panels and elements that can be set up quickly and successfully, reducing labor and product waste. Modular formwork is adaptable to different building sizes and shapes, making it ideal for diverse projects, from residential structures to large infrastructure works. Their reusability even more improves sustainability and cost-effectiveness, providing substantial benefits in project timelines and resource administration.

The selection between typical and modular formwork remedies depends on elements such as task range, budget, and desired coating top quality. With the expanding trends in building and construction effectiveness and sustainability, modular formwork systems are progressively preferred by professionals aiming to optimize productivity while keeping high criteria of safety and quality.

Types of Scaffolding

Scaffolding plays an important function in the construction sector, supplying important support and gain access to during numerous jobs. Various sorts of scaffolding cater to particular needs and atmospheres, guaranteeing safety and performance in the workplace. From traditional tube and clamp systems to modern-day modular options, understanding the various scaffolding kinds is vital for formwork and scaffolding firms aiming to enhance their procedures and supply superior services to their customers.

Solitary Scaffolding

Scaffolding is a crucial component in building and construction, supplying short-term support that allows employees to safely access different elevations and areas. Among the numerous sorts of scaffolding, solitary scaffolding sticks out for its simpleness and efficiency, particularly in smaller sized tasks. This type includes a single row of upright messages that are linked by horizontal beam of lights and planks.

- Fundamental Structure: Solitary scaffolding typically comprises vertical standards, horizontal journals, and wooden slabs that produce a system for workers.

- Usage Situation: Ideal for stonework job, where access to walls is required without complex support group.

- Alleviate of Setting Up: Quick and basic to erect, making it a popular option for smaller sized jobs or repair.

- Affordable: Generally requires fewer materials and less labor compared to much more complex scaffolding systems.

- Stability Factors to consider: Although stable for light tasks, it may not use the same level of support for heavy tons or tall frameworks as dual scaffolding.

Dual Scaffolding

Scaffolding plays an important function in building and construction and remodelling, offering momentary assistance frameworks that ensure safety and performance. Within the world of scaffolding, there are numerous kinds customized to particular requirements and challenges of construction websites. Recognizing these types is crucial for formwork and scaffolding business to supply top quality solutions.

One particular method of scaffolding is referred to as dual scaffolding, which is mostly used for masonry work where the wall surface being created is too thick for single scaffolding to sustain. This method includes two sets of scaffolding systems, supplying additional stability and safety and security.

- Single Scaffolding: Commonly made use of for brick stonework, sustaining only one side of the framework.

- Double Scaffolding: Utilizes 2 rows of scaffolding to enhance stability, perfect for thick walls and heavy masonry.

- Suspended Scaffolding: Systems that hang from an overhanging framework, appropriate for dealing with tall buildings and façades.

- Mobile Scaffolding: Movable scaffolding units that can be easily transferred throughout the worksite, boosting convenience.

- Shoring Scaffolding: A momentary structure utilized to support a building or structure while it's under repair work or construction.

When choosing the proper scaffolding kind, business have to consider variables such as the scope of job, height, and security laws. Double scaffolding, particularly, is necessary for ensuring employee safety and performance in challenging settings.

Suspended Scaffolding

Scaffolding is important in building, supplying support and gain access to for workers and materials. Amongst different scaffolding types, suspended scaffolding is specifically noteworthy. It is normally made use of for service structure exteriors, specifically high-rise structures, where conventional scaffolding may be unwise. This type of scaffolding is suspended from an above framework, allowing workers to safely do their jobs while minimizing the ground footprint.

Right here are some essential attributes and advantages of put on hold scaffolding:

- Convenience: Put on hold scaffolding can quickly adapt to various building shapes and elevations, making it suitable for various building and construction jobs.

- Space-saving: By being put on hold, this scaffolding type does not call for a large ground area, which is helpful in urban setups with minimal area.

- Availability: Supplies simple accessibility to hard-to-reach areas, allowing employees to efficiently execute tasks like painting, fixing, and cleansing.

- Safety and security: Made with safety and security features, consisting of guardrails and harness points, which help make certain employee safety at heights.

- Economical: Minimizes the need for considerable ground scaffolding systems, which can conserve time and expenses in labor and products.

Put on hold scaffolding is an important component in formwork and scaffolding companies, permitting optimum efficiency and safety in high-altitude atmospheres.

Rolling Scaffolding

Scaffolding is an important part in building and construction and renovation tasks, providing temporary structures to support employees and products. Among the various kinds of scaffolding, rolling scaffolding is especially notable for its flexibility and flexibility. This type features wheels or casters on the base, allowing it to be conveniently relocated from one area to an additional without disassembly. It is especially helpful in jobs that call for frequent access to various elevations and settings, such as paint, drywall setup, or maintenance work.

Rolling scaffolding is typically built from light weight aluminum or steel, ensuring toughness while staying light-weight for simple transport. The elevation can be adapted to accommodate various jobs, and it commonly consists of guardrails for added security. In addition, some models are developed to be used on irregular surface areas, making them suitable for both indoor and outside applications. Overall, rolling scaffolding gives a useful solution for employees needing a stable platform that can adapt to changing requirements on the work website.

Principal in the Industry

The formwork and scaffolding industry plays a vital function in the construction field, giving crucial support and safety during building jobs. Principal in this sector are known for their cutting-edge options and premium items, accommodating a diverse range of building and construction requirements. These business not just manufacture and supply formwork and scaffolding systems however likewise focus on advancing innovation and sustainability within their operations. As they continue to broaden their global presence, the impact of these sector leaders is felt in projects of all dimensions, driving performance and enhancing safety criteria across the building landscape.

Major Formwork Business

In the formwork and scaffolding industry, a number of principals stick out for their development, reliability, and market visibility. These companies are vital in shaping the infrastructure market by offering versatile and effective solutions for building projects globally. From big tasks like skyscrapers to smaller sized household structures, the role of these companies is vital.

One of the leading names in the market is PERI Team, recognized for its innovative formwork, scaffolding, and design services. With a solid emphasis on technology, PERI supplies customized services that cater to a range of building and construction demands.

Another significant gamer is Doka, a subsidiary of the Umdasch Group, which has a substantial impact in the global market. Doka's innovative formwork systems and dedication to quality make it a favored choice for specialists searching for longevity and efficiency.

Altrad Team is additionally significant, as it offers a substantial variety of solutions, including scaffolding and formwork remedies. With a focus on security and sustainability, Altrad aims to boost productivity on construction sites while adhering to environmental standards.

Other significant companies include Layher, which is renowned for its cutting-edge scaffolding remedies, and BrandSafway, that incorporates formwork, scaffolding, and accessibility options to meet the demands of numerous jobs. These companies, among others, add to a competitive landscape that continuously strives for innovation, safety, and operational performance in the formwork and scaffolding field.

Leading Scaffolding Providers

The formwork and scaffolding market is essential for construction jobs, giving vital assistance and security during building and restoration processes. Key players in this industry are understood for their innovative remedies, quality items, and strong market visibility, making them leaders in the area.

Among the leading scaffolding service providers is Layher, renowned for its high-quality modular scaffolding systems that offer convenience and efficiency on building websites. Their items are widely utilized throughout numerous markets, guaranteeing safety and dependability.

PERI, one more popular player, concentrates on formwork and scaffolding systems that deal with a variety of building and construction requirements. formwork waler and design know-how enable them to supply customized solutions that enhance productivity and safety and security on website.

Altrad Group is also a considerable name in the industry, offering an extensive range of scaffolding and accessibility options. They concentrate on supplying cost-effective and reliable products while keeping high security criteria across their operations.

BrandSafway stands apart for its innovative gain access to services and scaffolding services, serving markets from building to industrial maintenance. Their commitment to safety and quality makes them a relied on companion for massive jobs worldwide.

Each of these leading suppliers plays a vital function in shaping the scaffolding and formwork market by driving advancements in safety, effectiveness, and performance while meeting the diverse requirements of the building and construction market.

Emerging Gamers in the Market

The formwork and scaffolding market is important for the building market, giving essential support frameworks for building jobs. It is identified by a mix of established gamers and arising companies that are improving the market landscape.

Principal in the market consist of global giants such as PERI, Balfour Beatty, and Altrad Group, which are known for their extensive range of items, innovative remedies, and solid market presence. These companies have robust supply chains and a credibility for integrity, which is essential for large-scale construction jobs.

Emerging gamers are acquiring grip by concentrating on specific niche markets and brand-new modern technologies. Firms like Moddex and SkyScaff are investing in light-weight materials and modular designs that improve safety and efficiency. In addition, developments in electronic solutions for job monitoring and scaffolding style are ending up being essential for brand-new participants intending to distinguish themselves in an open market.

The evolving landscape also sees an expanding emphasis on sustainability, with brand-new companies exploring environmentally friendly products and techniques. This change not just lines up with sector trends but likewise attracts a consumer base that prioritizes environmental obligation.

As the construction market remains to expand globally, the interplay between these principals and emerging companies will form the future of formwork and scaffolding, driving advancement and boosting service delivery throughout the field.

Variables to Take Into Consideration When Selecting a Company

When picking a formwork and scaffolding company, several critical variables enter into play to make certain that the chosen companion lines up with project requirements and market criteria. The online reputation of the company, the quality of materials, safety and security techniques, and the variety of services used are important factors to consider that can significantly impact the success of building jobs. Recognizing these factors aids in making an informed choice, which eventually brings about safer, much more effective, and economical task execution.

Experience and Competence

When picking a formwork and scaffolding company, it's necessary to examine numerous aspects to make certain that the choice aligns with project requirements and standards. The appropriate company can substantially affect the success and security of building tasks. Right here are essential aspects to consider:

- Experience: A company with a proven track record is typically more trustworthy. Seek years in the sector and the number of projects finished.

- Know-how: Specialized knowledge in formwork and scaffolding makes certain that the business understands the complexities associated with different building and construction types.

- Safety and security Document: Explore the business's security techniques and background. Security must always be a priority in building and construction.

- Quality of Devices: The condition of scaffolding and formwork devices can considerably impact the general task quality and safety and security.

- Client Testimonials and Testimonials: Comments from previous clients can provide insights into the business's reliability and solution degree.

- Availability of Support: Strong client service and support can help address problems rapidly during the job.

By thinking about these elements meticulously, you can make an informed choice when choosing a formwork and scaffolding firm that fulfills the special demands of your building and construction job.

Top quality of Materials

When picking a formwork and scaffolding company, among one of the most essential aspects to take into consideration is the high quality of products utilized in their products. Top notch materials are important to make sure security, sturdiness, and total efficiency on building sites. If a company utilizes substandard or affordable materials, it might not only compromise the integrity of the structures yet could additionally result in possible mishaps and raised costs in the future because of repair services or replacements.

The type of products utilized can directly impact the weight-bearing capability and stability of scaffolding. For example, opting for companies that use durable steel or aluminum structures makes certain that the scaffolding can endure hefty lots and unfavorable weather conditions. In addition, companies that supply treated lumber or high-quality composite materials for formwork can provide better resistance to put on and damage, boosting the life-span of the equipment.

Additionally, it's crucial to inquire about the sourcing of products. Trusted firms usually have strict quality assurance procedures in position, making sure that all materials meet industry requirements and laws. This adherence not only ensures safety and security but likewise speaks with the company's dedication to professionalism and integrity.

Last but not least, consumer responses and evaluations can use beneficial understandings right into the efficiency of products made use of by a business. Satisfied customers will usually highlight the toughness and efficiency of the scaffolding and formwork systems they've made use of, giving a sense of confidence in the top quality used by the business.

Security Criteria

When selecting a formwork and scaffolding business, a number of important variables should be evaluated to make certain security and high quality in building and construction projects. Safety and security criteria are critical in this industry since they straight impact the health of workers and the surrounding environment.

Firstly, it's necessary to validate the firm's conformity with pertinent regulative bodies and safety and security criteria, such as OSHA (Occupational Security and Health Management) guidelines and local building codes. Firms with a tested record of sticking to these laws show a commitment to maintaining a safe working environment.

Next off, think about the business's security training programs for employees. A robust training routine guarantees that employees recognize the risks related to formwork and scaffolding and are outfitted to manage materials and equipment safely. Look for firms that provide continuous training and accreditation for their personnel.

Furthermore, assess the company's background of safety and security occurrences. A low case rate not only reflects reliable safety and security methods but likewise reveals an accountable approach to take the chance of administration. Request documentation of previous tasks to examine their efficiency criteria and just how they focus on security on-site.

An additional aspect to consider is the high quality and maintenance of tools utilized. Properly maintained scaffolding and formwork systems reduce the possibility of mishaps and architectural failings. Business that buy normal assessments and maintenance of their tools show a serious dedication to safety and security.

Ultimately, it is advantageous to look for testimonials and referrals from other customers. Comments from past clients regarding their experiences can provide insight into the business's integrity, high quality of solution, and adherence to safety criteria. By taking these factors right into account, one can make a more informed decision when choosing a scaffolding or formwork company.

Price Efficiency

Choosing a trustworthy formwork and scaffolding firm is crucial for the success of any type of building task. A number of variables play an essential duty in making this choice, particularly set you back effectiveness. Comprehending these elements can help make certain that the chosen firm meets your project needs without jeopardizing on quality or safety.

- Top quality of Materials: Assess the resilience and quality of the materials utilized by the business, as this will affect both safety and security and lasting costs.

- Prices Framework: Search for openness in the rates framework, consisting of any type of concealed costs that may emerge throughout the job.

- Experience and Reputation: Take into consideration the firm's track record and customer comments, as experienced companies commonly provide much better value via their proficiency.

- Shipment and Support Solutions: Review the performance of distribution and support solutions, as timely accessibility can significantly impact project timelines and overall costs.

- Custom Solutions: Determine if the business offers customized services that meet certain project needs, which can improve effectiveness and minimize waste.

By taking these aspects right into account, you can make an informed decision that balances cost effectiveness with the high quality and safety and security of formwork and scaffolding remedies.

Current Fads in Formwork and Scaffolding

The construction market is witnessing significant developments in formwork and scaffolding modern technologies, driven by the need for enhanced performance, security, and sustainability. Business are welcoming ingenious products and layout techniques, such as modular and light-weight systems, which help with quicker setting up and disassembly. Furthermore, the combination of digital tools and IoT modern technology is making it possible for real-time surveillance and enhanced task monitoring, thus changing standard practices. As the demand for urban construction continues to grow, these patterns are reshaping just how formwork and scaffolding business run, inevitably improving efficiency and minimizing ecological influences.

Raised Use Modern Technology

Current patterns in formwork and scaffolding reflect a significant shift in the direction of integrating advanced modern technologies. As building tasks come to be increasingly complicated and demanding, companies are embracing innovative services to improve effectiveness, security, and total task outcomes. Among one of the most notable trends is the boosted use of modern technology in various facets of formwork and scaffolding operations.

Secret technical innovations consist of:

- Digital preparation and design software that permits precise modeling and simulation of formwork systems.

- 3D printing innovation for creating customized formwork parts, reducing material waste and labor time.

- Robotics and automation in scaffolding setting up and disassembly, boosting safety and effectiveness on-site.

- Wearable modern technology for checking worker health and wellness, supplying real-time data to stop crashes.

- Assimilation of drones for site surveys and evaluations, making certain conformity and reducing time spent on hand-operated checks.

As these trends remain to develop, the formwork and scaffolding industry is most likely to see a better focus on lasting practices and enhanced cooperation between business and technology providers.

Sustainability Campaigns

Present patterns in formwork and scaffolding mirror an expanding emphasis on technology, efficiency, and sustainability in the building and construction industry. As projects become extra intricate and demand for faster completion increases, companies are adopting advanced materials and modern technologies that enhance security and decrease building time.

One considerable fad is using modular and pre-fabricated systems. These solutions allow quicker assembly and disassembly on site, lessening labor prices and boosting performance. Prefabrication likewise adds to better quality control, as elements are made in a regulated setting before being transported to the building site.

Sustainability campaigns go to the center of the sector's development. Many formwork and scaffolding firms are focusing on eco-friendly materials and methods. Choices such as recyclable formwork systems assist to lower waste, while light-weight products decrease the carbon impact connected with transportation. Additionally, business are incorporating electronic technology in their style and administration processes to optimize source use and advertise energy performance.

Additionally, the trend in the direction of circular economy principles is getting energy. By prioritizing the reuse and recycling of formwork and scaffolding products, business not just lower their ecological influence but additionally line up with expanding policies and market needs for lasting techniques.

Finally, improvements in security innovation are likewise affecting present patterns. Advancements such as wearable security gadgets and automated scaffolding systems are enhancing employee safety and security on task sites, resolving one of the market's critical challenges while fostering a culture of safety-centric techniques.

Prefabrication and Modular Building

The construction sector is experiencing substantial modifications, driven by improvements in technology and a growing focus on effectiveness and sustainability. Current fads in formwork and scaffolding, in addition to prefabrication and modular building and construction, are improving how tasks are performed and handled, enabling faster completion times and minimized prices.

One of the most noteworthy patterns in formwork and scaffolding is the shift in the direction of digitalization. Companies are progressively adopting Structure Info Modeling (BIM) to improve preparation and implementation processes. This technical integration allows for much better visualization, sychronisation, and administration of materials, minimizing the opportunities of mistakes and boosting overall task effectiveness.

Sustainability plays an important duty in the existing landscape, with an increased focus on environmentally friendly materials and methods. Formwork and scaffolding firms are exploring options that decrease waste and use recyclable and lasting materials. This not just meets governing demands yet also attract customers who focus on ecological duty in their job option.

In addition, prefabrication and modular construction are acquiring traction, using services that considerably reduce on-site building time. By shifting much of the building process off-site, companies can enhance quality control and reduce labor expenses. These approaches allow for faster job distribution and less disruption in city environments.

The use of sophisticated materials such as lightweight and high-strength compounds is additionally transforming the formwork and scaffolding sector. These products are not just more sturdy however additionally much easier to deal with, which contributes to boosted security on construction websites. Firms are starting to prioritize not only the performance of their systems yet also their flexibility and reusability for different projects.

As jobs end up being more complex, there is a growing need for smart scaffolding solutions that integrate sensing units and IoT modern technology. These technologies enable real-time tracking of structural stability and employee security, offering beneficial information that can result in more enlightened decision-making.

In recap, the landscape of formwork and scaffolding is evolving swiftly, driven by digitalization, sustainability, prefabrication, and ingenious materials. As the building industry remains to welcome these patterns, companies that adjust early will likely obtain an one-upmanship in this vibrant market.

Challenges Faced by the Sector

The formwork and scaffolding sector plays an important function in construction, providing necessary assistance structures for constructing tasks. Nevertheless, directory in this field encounter a myriad of difficulties that can affect their operations and profitability. These difficulties consist of changing product expenses, rigorous safety and security laws, and the requirement for knowledgeable labor, every one of which can complicate task timelines and budgets. In addition, the ongoing promote sustainability and advancement requires firms to continually adjust and boost their methodologies to remain competitive in a developing market.

Governing Compliance

Formwork and scaffolding companies operate in an intricate atmosphere where they encounter many challenges, specifically in the world of regulatory compliance. This industry is greatly regulated due to the safety and security threats related to building tasks, that makes adherence to guidelines crucial for functional success.

Among the main difficulties is the ever-changing landscape of neighborhood, national, and global laws. Companies should remain updated on numerous codes and criteria, which can differ substantially by territory. This needs ongoing training and resources to ensure that all team member are well-informed regarding the most recent conformity needs.

Another concern is the considerable financial burden that governing compliance can impose. The price of executing precaution, obtaining required accreditations, and training workers can be significant, especially for smaller companies. These economic pressures might cause firms reducing corners, presenting severe threats to safety and overall task success.

Furthermore, the intricacy of conformity documents can be daunting. Formwork and scaffolding firms frequently take part in tasks with several stakeholders, each with their own conformity needs. Working with these various guidelines can result in hold-ups and increase the potential for miscommunication, which might inevitably threaten the safety of employees on site.

Ultimately, the market deals with challenges related to technological innovations. As brand-new products and building and construction approaches emerge, regulatory bodies often require time to overtake these growths. Business that purchase ingenious practices must navigate a. absence of clear assistance on conformity, making it challenging to embrace new innovations without running the risk of non-compliance.

In recap, formwork and scaffolding business confront substantial difficulties associated with regulative compliance, including adapting to transforming laws, taking care of economic concerns, browsing intricate paperwork, and incorporating new innovations. Attending to these problems is essential for guaranteeing safety and security and maintaining affordable benefit in the industry.

Labor Lacks

The formwork and scaffolding sector is presently facing a number of difficulties that impede its development and effectiveness. Among these, labor lacks stand out as a considerable concern, influencing job timelines and cost administration. The sector requires competent workers to make sure appropriate setup and safety measures, yet attracting and keeping such talent has become progressively challenging.

One adding element to this labor lack is the aging labor force. Lots of experienced employees are getting to old age, and there are insufficient younger individuals getting in the field to replace them. Additionally, the perception of construction-related tasks as demanding and often less preferable has actually discouraged possible candidates from going after professions in this market.

In addition, the recurring competition for knowledgeable labor across numerous trades intensifies the problem. Industries such as pipes, electrical, and general building often provide similar task opportunities yet might give much better rewards or functioning conditions, drawing potential ability away from formwork and scaffolding roles.

To tackle these challenges, firms are buying training programs to upskill existing employees and draw in novices. Collaborations with profession colleges and universities to promote occupations in formwork and scaffolding can help connect the void and develop a much more durable workforce. Nevertheless, resolving the labor scarcity remains a crucial and continuous effort for the industry.

Market Competition

The formwork and scaffolding market plays a vital function in building and construction jobs, providing important assistance structures for structure and restoration. Nonetheless, business in this market face many obstacles that impact their operations and profitability. One considerable obstacle is the enhancing competition within the market, which has magnified because of both regional and international players getting in the arena. This competition puts pressure on pricing, as firms make every effort to supply worth while keeping quality and security requirements.

Another challenge is the variation in basic material prices, which can significantly impact functional expenses. Firms have to navigate these rate changes while ensuring their products fulfill sector safety laws and efficiency assumptions. In addition, fast developments in modern technology require companies to constantly innovate and adjust to brand-new techniques and products, which can strain sources and call for significant investment.

Labor force concerns additionally existing difficulties for the sector. Competent labor scarcities develop troubles in keeping efficiency and meeting project deadlines. Business have to invest in training programs and attract ability to get rid of these shortages, which can be resource-intensive.

Furthermore, financial uncertainty, often driven by worldwide occasions or changes in federal government plans, can lead to rising and fall need for construction solutions. Formwork and scaffolding firms need to be dexterous and all set to readjust their strategies to continue to be affordable throughout declines. To conclude, getting over these challenges calls for a durable approach, financial investment in development, and a dedication to workforce development to thrive in a very competitive market.

Future Expectation

The future overview for formwork and scaffolding firms is poised for significant change, driven by developments in modern technology, an increase in infrastructure tasks, and an increased concentrate on security and sustainability. As the building industry progresses, these companies are anticipated to embrace cutting-edge solutions that boost performance and decrease costs. Additionally, the growing need for environmentally friendly techniques will challenge companies to integrate sustainable materials and methods into their procedures, placing them for success in a competitive market. This vibrant landscape offers both possibilities and challenges, motivating industry leaders to adjust quickly to satisfy the altering requirements of customers and regulative requirements.

Market Development Projections

The future outlook for formwork and scaffolding firms appears encouraging, driven by numerous aspects adding to market growth. As building and construction tasks ramp up worldwide, there is an increasing demand for sophisticated and effective formwork and scaffolding remedies. The market is anticipated to witness substantial growth, underpinned by technological advancements and the demand for much safer building techniques.

Trick forecasts influencing market development consist of:

- Growth of construction projects in emerging markets.

- Boosted investments in infrastructure development.

- Rising fostering of cutting-edge formwork systems and products.

- Growing understanding of safety and security laws and requirements in the building market.

- Change in the direction of modular and premade construction methods.

As these patterns continue to progress, formwork and scaffolding business that adjust to brand-new modern technologies and concentrate on lasting techniques are likely to find enhanced possibilities for growth and market infiltration.

Developments coming up

The future expectation for formwork and scaffolding business is positioned for significant transformation, driven by improvements in technology, sustainability campaigns, and advancing building approaches. As facilities demands expand, the sector is adapting to satisfy new obstacles, while likewise accepting developments that promise to improve efficiency and security on work sites.

Among one of the most remarkable trends is the increasing assimilation of digital technologies, specifically Building Information Modeling (BIM) and increased truth (AR). These devices enable boosted preparation, visualization, and coordination amongst teams, minimizing mistakes and boosting task timelines. The execution of IoT (Net of Things) gadgets is additionally increasing, giving real-time information on devices use and website problems, guaranteeing optimum performance and safety and security criteria.

Sustainability remains a crucial focus, with firms looking for eco-friendly products and techniques. Innovations in lightweight and recyclable products are being developed, allowing for decreased waste and reduced carbon footprints throughout building and construction procedures. These eco-conscious practices not only profit the setting but additionally interest a growing market that values sustainability in construction.

Automation and robotics are set to revolutionize scaffolding and formwork setup. Business are discovering automated systems that can deal with repetitive tasks a lot more effectively, thus enhancing performance and lowering labor expenses. Using drones for site assessment and supervision is additionally being explored, providing airborne understandings that can improve task management and oversight.

On top of that, the continuous advancement of safety methods and devices is critical. Enhanced safety gear and smart security systems will likely be established to better secure workers on-site. Training programs utilizing online reality can supply immersive discovering experiences for employees, much better preparing them for the challenges they might deal with in real-world scenarios.

Generally, the future for formwork and scaffolding firms is bright, identified by innovation and a commitment to safety and security and sustainability. As the industry remains to embrace these developments, it will certainly not just enhance functional performance however additionally place itself as a leader in the ever-evolving construction landscape.

Impact of Economic Issues

The future overview for formwork and scaffolding firms is elaborately connected to the dominating financial conditions. As the building and construction sector is directly influenced by economic development, changes in GDP, rates of interest, and investment levels play an essential role in shaping the demand for these crucial services.

In a thriving economy, facilities jobs have a tendency to increase, leading to greater financial investments in building. This pattern enhances the need for formwork and scaffolding services, making it possible for business to broaden their procedures and introduce their offerings. In addition, government efforts targeted at improving transportation and city growth existing additional possibilities for growth.

Alternatively, economic declines can position significant challenges for the industry. Economic downturns frequently bring about decreased building and construction budget plans, task hold-ups, and a decline in new domestic and industrial developments. In such circumstances, formwork and scaffolding business might face heightened competitors, rate pressures, and the requirement to simplify operations to preserve earnings.

Additionally, the impact of worldwide trade characteristics and supply chain interruptions can likewise affect these firms. Enhanced product prices or lacks can hinder task implementation and productivity. Staying dexterous and adapting to these economic changes will certainly be vital for formwork and scaffolding companies to ensure their sustainability and growth in future markets.